Click on any image below to zoom in for a closer look. Click the zoomed image to restore it to the original size.

Laser Tracker inspection of machined parts for oil drilling rigs.

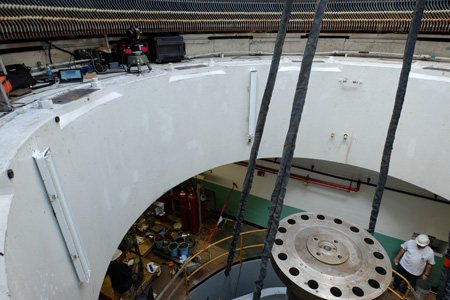

Laser Tracker inspection of machined flanges of wicket gate actuators, stator plumb

and concentricity, rotor pole radius and concentricity at the Folsom dam in Folsom, California.

and concentricity, rotor pole radius and concentricity at the Folsom dam in Folsom, California.

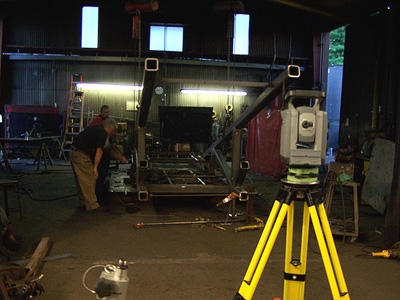

Alignment of boring bars for heel pins and new boom component monitoring

during weld out for concrete powder silo at Glacier Concrete in Portland, Oregon.

during weld out for concrete powder silo at Glacier Concrete in Portland, Oregon.

Alignment of pump shaft bearing and upper shaft bearing stuffing box for the fish ladder water supply at the John Day dam in Rufus, Oregon.

Performed a dimensional inspection of the existing tainter gate heel pins using

a Laser Tracker and a Portable CMM arm at the Lookout Point dam in Lowell, Oregon.

a Laser Tracker and a Portable CMM arm at the Lookout Point dam in Lowell, Oregon.

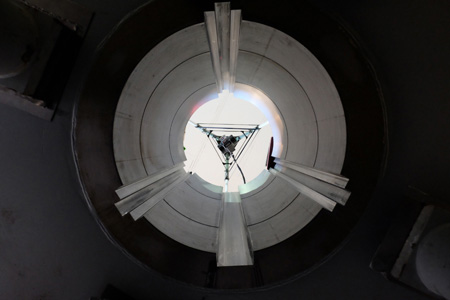

Laser Tracker inspection of rotor hub bore and keyways, stator plumb and

concentricity, rotor pole radius and concentricity at the Morony dam in Great Falls, Montana

concentricity, rotor pole radius and concentricity at the Morony dam in Great Falls, Montana

Precision monitoring of possible structural deformation in concrete grain elevator in Vancouver, Washington.